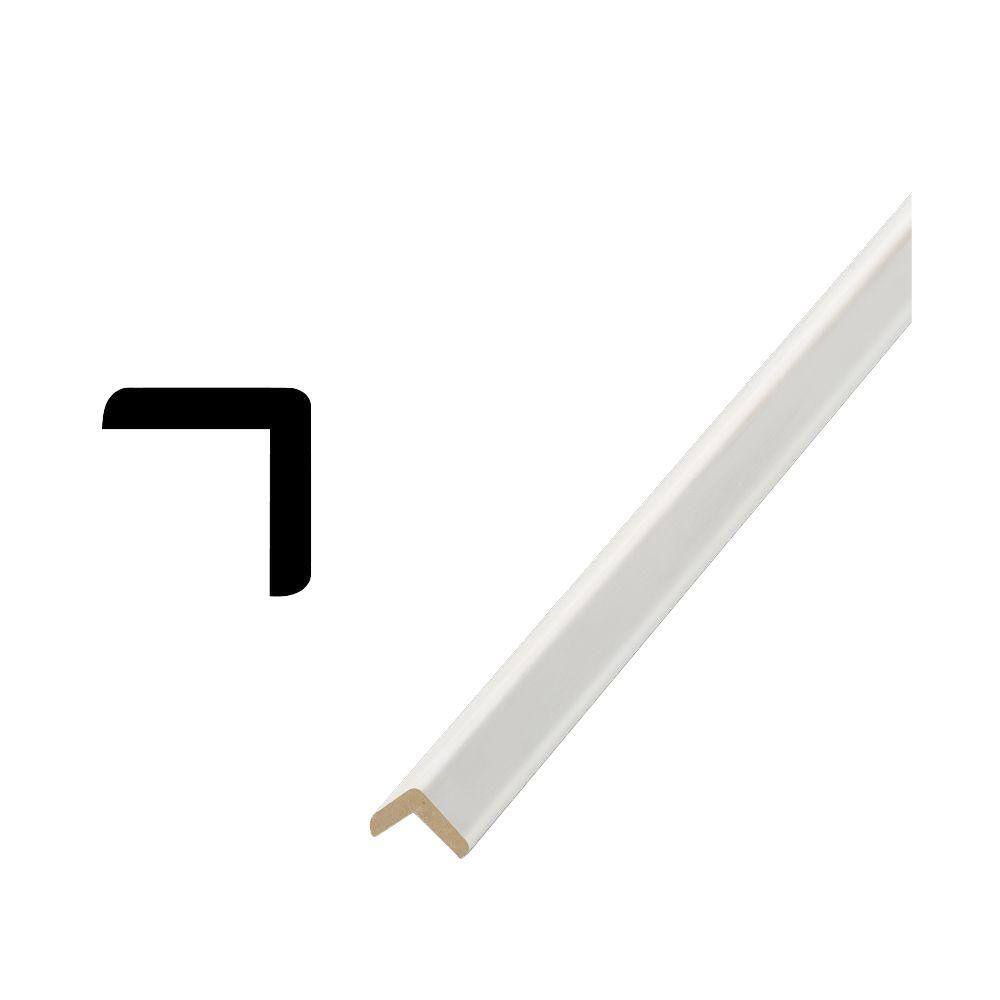

What is exterior corner moulding?

Exterior corner moulding is a type of trim that is used to cover and protect the outside corners of a building. It is typically made of wood, vinyl, or aluminum, and it can be either plain or decorative.

Editor’s Notes: Exterior corner moulding is an important part of a building’s exterior, as it helps to protect the building from the elements and adds a finished look.

Our team of experts has done the research and gathered all the necessary information about exterior corner moulding. We put together this guide to help you make the right decision for your home.

Key differences or Key takeaways:

| Feature | Wood | Vinyl | Aluminum |

|---|---|---|---|

| Durability | Good | Excellent | Excellent |

| Cost | Moderate | Low | High |

| Maintenance | Requires painting or staining | Low maintenance | No maintenance |

Main article topics:

- Types of exterior corner moulding

- How to install exterior corner moulding

- Benefits of using exterior corner moulding

Exterior corner moulding

Exterior corner moulding is an essential part of a building’s exterior, as it helps to protect the building from the elements and adds a finished look. Here are 10 key aspects of exterior corner moulding to consider:

- Material: Wood, vinyl, or aluminum

- Style: Plain or decorative

- Size: Width and thickness

- Installation: Nail, screw, or adhesive

- Maintenance: Painting, staining, or cleaning

- Durability: Resistance to weather, rot, and insects

- Cost: Varies depending on material, style, and size

- Benefits: Protection, aesthetics, and value

- Types: Outside corner moulding, inside corner moulding, and casing

- Accessories: Corner blocks, miter joints, and caulk

When choosing exterior corner moulding, it is important to consider the material, style, size, and installation method that best suits your needs. Wood is a classic choice that is durable and easy to paint or stain. Vinyl is a low-maintenance option that is available in a variety of colors and styles. Aluminum is a strong and durable option that is also resistant to rust and corrosion.Exterior corner moulding is a relatively small detail, but it can make a big difference in the overall appearance of your home. By taking the time to choose the right type of moulding, you can add a touch of style and sophistication to your home’s exterior.

Material

The material of exterior corner moulding is an important consideration, as it will affect the durability, maintenance, and cost of the moulding. Wood is a classic choice that is durable and easy to paint or stain. Vinyl is a low-maintenance option that is available in a variety of colors and styles. Aluminum is a strong and durable option that is also resistant to rust and corrosion.

The table below provides a comparison of the three materials:

| Material | Durability | Maintenance | Cost |

|---|---|---|---|

| Wood | Good | Requires painting or staining | Moderate |

| Vinyl | Excellent | Low maintenance | Low |

| Aluminum | Excellent | No maintenance | High |

When choosing a material for exterior corner moulding, it is important to consider the climate in which you live, the style of your home, and your budget. If you live in a harsh climate, you will need a material that is durable and weather-resistant. If you have a traditional home, you may prefer wood moulding. If you have a modern home, you may prefer vinyl or aluminum moulding.

No matter what material you choose, exterior corner moulding is an important part of your home’s exterior. It helps to protect your home from the elements and adds a finished look.

Style

The style of exterior corner moulding can vary from plain to decorative, depending on the desired look of the home. Plain moulding is simple and understated, while decorative moulding can add a touch of elegance or flair.

-

Plain exterior corner moulding

Plain exterior corner moulding is a simple and understated option that can complement any style of home. It is typically made of wood, vinyl, or aluminum, and it can be either square or rounded. Plain exterior corner moulding is a good choice for homes that have a traditional or modern style.

-

Decorative exterior corner moulding

Decorative exterior corner moulding can add a touch of elegance or flair to any home. It is typically made of wood or polyurethane, and it can be carved with a variety of designs. Decorative exterior corner moulding is a good choice for homes that have a Victorian, Colonial, or Craftsman style.

When choosing the style of exterior corner moulding for your home, it is important to consider the overall style of your home, as well as your personal preferences. If you are unsure of what style to choose, you can always consult with a professional.

Size

The size of exterior corner moulding, including its width and thickness, plays a crucial role in determining its functionality and aesthetic appeal. Here are key aspects to consider:

-

Width

The width of exterior corner moulding refers to its measurement from one side to the other. It influences the visibility and prominence of the moulding. Wider moulding creates a more noticeable accent, while narrower moulding provides a subtle touch. The width should complement the size and style of the building.

-

Thickness

The thickness of exterior corner moulding determines its durability and strength. Thicker moulding is more resistant to damage from impact or weather conditions. However, it can also be more expensive and may require additional support during installation. The thickness should be appropriate for the location and exposure of the moulding.

When selecting the size of exterior corner moulding, it is essential to consider the architectural style of the building, the size of the area being trimmed, and the desired level of visibility. Proper sizing ensures the moulding enhances the aesthetics and protects the building effectively.

Installation

The installation method of exterior corner moulding, whether by nail, screw, or adhesive, significantly impacts its functionality and longevity. Here’s a closer look at each method and its implications:

Nails

Nails are a traditional and widely used method for installing exterior corner moulding. They are relatively easy to use and provide a secure hold. However, nails can be prone to rust and corrosion over time, especially in humid or coastal environments. Additionally, nailing can split or damage the moulding if not done carefully.

Screws

Screws offer a stronger and more durable alternative to nails. They are less likely to rust or corrode and provide a more secure hold, reducing the risk of the moulding coming loose. Screws are also easier to remove and adjust if necessary.

Adhesive

Adhesive is a convenient and versatile option for installing exterior corner moulding, particularly on surfaces where nailing or screwing is not feasible. It provides a strong bond and eliminates the need for visible fasteners. However, the effectiveness of adhesive depends on the type of adhesive used and the surface it is applied to. It may not be suitable for all types of moulding or in extreme weather conditions.

The choice of installation method should consider factors such as the type of moulding, the surface it is being installed on, and the desired level of durability. For long-lasting and secure installation, screws are generally the preferred option. However, nails can be a cost-effective alternative, and adhesive can be useful in specific situations where nailing or screwing is not practical.

Maintenance

Exterior corner moulding requires regular maintenance to preserve its appearance and longevity. This includes painting, staining, or cleaning, depending on the material of the moulding.

-

Painting

Painted exterior corner moulding requires periodic repainting to maintain its color and protect it from the elements. The frequency of repainting depends on the type of paint used and the climate in which the moulding is installed. In general, repainting should be done every 3-5 years.

-

Staining

Stained exterior corner moulding requires periodic re-staining to maintain its color and protect it from the elements. The frequency of re-staining depends on the type of stain used and the climate in which the moulding is installed. In general, re-staining should be done every 2-3 years.

-

Cleaning

All types of exterior corner moulding require regular cleaning to remove dirt, dust, and other debris. This can be done with a mild soap and water solution and a soft cloth. Avoid using harsh chemicals or abrasive cleaners, as these can damage the moulding.

Proper maintenance of exterior corner moulding is essential to ensure that it continues to perform its function of protecting the building from the elements and enhancing its appearance. By following the recommended maintenance schedule, homeowners can extend the lifespan of their exterior corner moulding and keep their home looking its best.

Durability

Durability is a key factor to consider when choosing exterior corner moulding. The moulding must be able to withstand the elements, including rain, snow, sun, and wind. It must also be resistant to rot and insects. Otherwise, the moulding will deteriorate quickly and need to be replaced.

-

Resistance to weather

Exterior corner moulding is exposed to the elements, so it must be able to withstand rain, snow, sun, and wind. The moulding should be made of a material that is not easily damaged by moisture or UV rays.

-

Resistance to rot

Rot is a common problem for exterior wood moulding. Rot is caused by fungi that feed on the wood, causing it to decay. The moulding should be made of a material that is resistant to rot, such as cedar or redwood.

-

Resistance to insects

Insects can also damage exterior corner moulding. Insects, such as termites and carpenter ants, can eat the wood, causing it to weaken and deteriorate. The moulding should be made of a material that is resistant to insects, such as pressure-treated wood.

By choosing exterior corner moulding that is durable and resistant to weather, rot, and insects, you can ensure that your moulding will last for many years to come.

Cost

The cost of exterior corner moulding varies depending on the material, style, and size. The material of the moulding is the most significant factor in determining its cost. Wood moulding is typically the most expensive, followed by vinyl and then aluminum. The style of the moulding also affects its cost, with more decorative mouldings costing more than plain mouldings. The size of the moulding is also a factor, with larger mouldings costing more than smaller mouldings.

It is important to consider the cost of exterior corner moulding when budgeting for a home improvement project. The cost of the moulding will vary depending on the specific needs of the project. For example, a large home with a complex roofline will require more moulding than a small home with a simple roofline. Additionally, the cost of the moulding will be higher if it is made of a high-quality material, such as wood or aluminum.

The following table provides a general overview of the cost of exterior corner moulding, depending on the material, style, and size:

| Material | Style | Size | Cost |

|---|---|---|---|

| Wood | Plain | 1″ x 1″ | $1-$2 per foot |

| Wood | Decorative | 1″ x 1″ | $2-$4 per foot |

| Vinyl | Plain | 1″ x 1″ | $0.50-$1 per foot |

| Vinyl | Decorative | 1″ x 1″ | $1-$2 per foot |

| Aluminum | Plain | 1″ x 1″ | $1-$2 per foot |

| Aluminum | Decorative | 1″ x 1″ | $2-$4 per foot |

When choosing exterior corner moulding, it is important to consider the cost of the moulding in addition to the other factors discussed above. By understanding the cost of the moulding, homeowners can make an informed decision about the best type of moulding for their needs.

Benefits

Exterior corner moulding offers a range of benefits for buildings, including protection, aesthetics, and value. It serves as a protective barrier against the elements, enhances the visual appeal of a structure, and contributes to its overall worth.

-

Protection

Exterior corner moulding acts as a protective layer for the vulnerable corners of a building. It shields these areas from moisture penetration, preventing water damage and structural issues. By deflecting rainwater and snow, the moulding helps maintain the integrity of the building’s exterior.

-

Aesthetics

Corner moulding plays a significant role in enhancing the aesthetic appeal of a building. It adds definition and character to the structure, framing windows, doors, and other architectural features. With a variety of styles and materials available, exterior corner moulding can complement any architectural style, from traditional to contemporary.

-

Value

The installation of exterior corner moulding not only improves the appearance of a building but also increases its value. Well-maintained corner moulding contributes to the overall curb appeal of a property, making it more attractive to potential buyers. Additionally, the protective benefits of corner moulding can extend the lifespan of a building, reducing maintenance costs and enhancing its long-term value.

By providing protection, enhancing aesthetics, and contributing to the value of a building, exterior corner moulding is a worthwhile investment for homeowners looking to improve the functionality and appearance of their property.

Types

Exterior corner moulding is a crucial element in the construction and aesthetics of a building’s exterior. It serves various purposes, including protecting the building from the elements, enhancing its visual appeal, and increasing its value. To fully understand the significance of exterior corner moulding, it is essential to explore its different types, namely outside corner moulding, inside corner moulding, and casing.

-

Outside corner moulding

Outside corner moulding is used to cover and protect the outside corners of a building. It is installed on the exterior walls and helps to prevent water damage and structural issues by deflecting rainwater and snow. Outside corner moulding also adds a decorative touch to a building’s exterior, enhancing its overall visual appeal.

-

Inside corner moulding

Inside corner moulding is used to cover and protect the inside corners of a building. It is installed on the interior walls and helps to prevent drywall damage and cracking. Inside corner moulding also adds a decorative touch to a building’s interior, framing windows, doors, and other architectural features.

-

Casing

Casing is a type of exterior corner moulding that is used to frame windows and doors. It is installed around the perimeter of the window or door and helps to create a finished look. Casing also helps to protect the window or door from the elements and adds a decorative touch to the building’s exterior.

Understanding the different types of exterior corner moulding and their specific functions is essential for choosing the right type of moulding for a particular application. By selecting the appropriate type of moulding, homeowners and builders can ensure that their buildings are well-protected from the elements, visually appealing, and valuable.

Accessories

Accessories play a crucial role in enhancing the functionality and aesthetics of exterior corner moulding. They provide additional support, ensure a seamless finish, and contribute to the overall durability of the moulding.

-

Corner blocks

Corner blocks are small, triangular blocks used to reinforce the corners of exterior corner moulding. They provide additional support and help to prevent the moulding from splitting or cracking. Corner blocks are typically made of the same material as the moulding and can be installed using nails or screws.

-

Miter joints

Miter joints are used to connect two pieces of exterior corner moulding at a 45-degree angle. They are typically used to create a seamless corner joint. Miter joints can be cut using a miter saw or a miter box. It is important to ensure that the miter joints are cut accurately to ensure a tight fit.

-

Caulk

Caulk is a sealant used to fill gaps and prevent water penetration. It is typically applied around the edges of exterior corner moulding to prevent water from seeping behind the moulding and causing damage to the underlying structure. Caulk is available in a variety of colors to match the moulding.

These accessories work together to ensure that exterior corner moulding is installed correctly and performs its intended functions effectively. Corner blocks provide support, miter joints create seamless connections, and caulk prevents water penetration. By using the appropriate accessories, homeowners and builders can ensure that their exterior corner moulding is durable, aesthetically pleasing, and protects the building from the elements.

FAQs on Exterior Corner Moulding

Exterior corner moulding is an essential element of a building’s exterior, providing both protection and aesthetic appeal. Here are answers to some frequently asked questions about exterior corner moulding:

Question 1: What is the purpose of exterior corner moulding?

Exterior corner moulding serves several important purposes. It protects the vulnerable corners of a building from moisture penetration, preventing water damage and structural issues. It also enhances the visual appeal of a building, adding definition and character to the structure. Additionally, exterior corner moulding can increase the value of a property by improving its overall curb appeal and extending the lifespan of the building.

Question 2: What materials are commonly used for exterior corner moulding?

Exterior corner moulding is typically made of wood, vinyl, or aluminum. Wood is a classic choice that is durable and easy to paint or stain. Vinyl is a low-maintenance option that is available in a variety of colors and styles. Aluminum is a strong and durable option that is also resistant to rust and corrosion.

Question 3: How is exterior corner moulding installed?

Exterior corner moulding can be installed using nails, screws, or adhesive. The installation method depends on the material of the moulding and the surface it is being installed on. It is important to follow the manufacturer’s instructions for proper installation.

Question 4: How often should exterior corner moulding be replaced?

The lifespan of exterior corner moulding depends on the material and the climate in which it is installed. Wood moulding typically needs to be replaced every 10-15 years, while vinyl and aluminum moulding can last for 20 years or more. Regular maintenance, such as painting or staining wood moulding, can extend its lifespan.

Question 5: What are some tips for choosing the right exterior corner moulding?

When choosing exterior corner moulding, consider the following factors: the material, style, size, and cost. The material should be durable and resistant to the elements. The style should complement the architectural style of the building. The size should be appropriate for the size of the building. The cost should fit within the budget for the project.

Question 6: Can exterior corner moulding be painted?

Yes, exterior corner moulding can be painted. However, it is important to use a paint that is specifically designed for exterior use. Exterior paint is more durable and resistant to fading and peeling than interior paint.

Summary: Exterior corner moulding is an important part of a building’s exterior, providing both protection and aesthetic appeal. When choosing and installing exterior corner moulding, consider the material, style, size, and cost. By following these tips, you can ensure that your exterior corner moulding will last for many years to come.

Transition to the next article section: In the next section, we will discuss the different types of exterior corner moulding and their specific functions.

Exterior Corner Moulding Tips

Exterior corner moulding is an essential element of a building’s exterior, providing both protection and aesthetic appeal. Here are some tips to help you choose and install exterior corner moulding:

Tip 1: Choose the Right Material

The material of your exterior corner moulding should be durable and resistant to the elements. Wood is a classic choice, but it requires regular maintenance. Vinyl is a low-maintenance option, but it is not as durable as wood. Aluminum is a strong and durable option, but it can be more expensive than wood or vinyl.

Tip 2: Choose the Right Style

The style of your exterior corner moulding should complement the architectural style of your home. There are many different styles of exterior corner moulding available, from simple to ornate. Choose a style that will enhance the overall look of your home.

Tip 3: Choose the Right Size

The size of your exterior corner moulding should be appropriate for the size of your home. Larger homes require larger corner moulding, while smaller homes can get away with smaller corner moulding. Be sure to choose a size that will look proportionate to your home.

Tip 4: Install the Moulding Correctly

Exterior corner moulding should be installed correctly in order to ensure that it will last for many years to come. Be sure to follow the manufacturer’s instructions for installation.

Tip 5: Maintain the Moulding

Exterior corner moulding requires regular maintenance to keep it looking its best. Be sure to clean the moulding regularly and repaint or stain it as needed.

Summary: By following these tips, you can choose and install exterior corner moulding that will protect your home from the elements and enhance its curb appeal for many years to come.

Transition to the conclusion: Exterior corner moulding is an important part of your home’s exterior. By following these tips, you can choose and install corner moulding that will protect your home and enhance its beauty for many years to come.

Exterior Corner Moulding

Exterior corner moulding is an important element of a building’s exterior, providing both protection and aesthetic appeal. When choosing and installing exterior corner moulding, consider the material, style, size, and cost. By following these tips, you can ensure that your exterior corner moulding will last for many years to come.

Exterior corner moulding not only protects your home from the elements but also enhances its curb appeal. By choosing the right material, style, and size, you can create a beautiful and durable exterior that will last for many years to come.

Youtube Video: