Tired of tangled wires and unsightly connections? Exterior junction boxes offer a clean and organized solution for your outdoor electrical needs!

Editor’s Note: Our comprehensive exterior junction box guide, published today, provides valuable insights to help you make informed decisions about your electrical projects.

After analyzing various products and digging into the latest information, we’ve put together this guide to help you choose the right exterior junction box for your specific needs.

Key Differences:

| Feature | Option 1 | Option 2 |

|---|---|---|

| Material | Durable plastic | Corrosion-resistant metal |

| Capacity | 4-6 connections | 8-10 connections |

| Waterproof | IP65 rating | IP67 rating |

Main Article Topics:

- Types of exterior junction boxes

- Factors to consider when choosing an exterior junction box

- Benefits of using an exterior junction box

- Installation tips for exterior junction boxes

- Troubleshooting common problems with exterior junction boxes

Exterior Junction Box

Exterior junction boxes play a crucial role in protecting electrical connections outdoors. Here are 9 key aspects to consider:

- Material: Durable plastic or corrosion-resistant metal

- Capacity: 4-10 connections

- Waterproof: IP65 or IP67 rating

- Size: Compact to large

- Shape: Rectangular, square, or round

- Knockouts: Pre-molded holes for cable entry

- Mounting: Wall-mount, pole-mount, or ground-mount

- Code compliance: Meets electrical codes and standards

- Warranty: Typically 1-5 years

These aspects are interconnected and should be considered together when choosing an exterior junction box. For example, the material and IP rating will determine the box’s durability and resistance to weather conditions. The size and shape will affect the number of connections and the ease of installation. The knockouts and mounting options will determine the flexibility of the box’s placement. By understanding these key aspects, you can select the right exterior junction box for your specific needs and ensure a safe and reliable electrical connection.

Material

The material of an exterior junction box plays a critical role in its durability, performance, and suitability for different environments. Here are two main material options to consider:

-

Durable Plastic:

Plastic exterior junction boxes are lightweight, economical, and offer good insulation. They are often made of impact-resistant materials like polycarbonate or ABS, which can withstand harsh weather conditions and UV rays. Plastic junction boxes are suitable for residential and light commercial applications where corrosion resistance is not a major concern.

-

Corrosion-Resistant Metal:

Metal exterior junction boxes are more durable and offer superior protection against corrosion, making them ideal for industrial and outdoor applications. They are typically made of galvanized steel or aluminum, which can withstand extreme temperatures, moisture, and chemical exposure. Metal junction boxes are more expensive than plastic ones but provide increased longevity and reliability in harsh environments.

When choosing the right material for your exterior junction box, consider the specific environmental conditions and the level of protection required. For applications where durability and corrosion resistance are paramount, metal junction boxes are the preferred choice. For cost-effective solutions in less demanding environments, plastic junction boxes offer a practical option.

Capacity

The capacity of an exterior junction box, typically ranging from 4 to 10 connections, plays a crucial role in determining the number of electrical devices or cables that can be accommodated within the box. This capacity is a crucial consideration for various reasons:

1. Safety and Code Compliance: Electrical codes and standards often specify the maximum number of connections allowed in a junction box based on the box’s size and material. Exceeding the capacity can lead to overcrowding, overheating, and potential safety hazards.

2. Functionality and Convenience: The capacity of the junction box directly affects the number of devices or cables that can be connected. A junction box with insufficient capacity may not be able to accommodate all the necessary connections, leading to a cluttered and disorganized installation. Conversely, a junction box with ample capacity provides room for future expansion and simplifies maintenance.

3. Space Optimization: Exterior junction boxes are often installed in limited spaces, such as walls, ceilings, or poles. Choosing the right capacity ensures that the box is not too large or too small for the available space. A properly sized junction box can provide adequate space for connections without being bulky or obtrusive.

4. Cost-Effectiveness: Junction boxes are available in various sizes and capacities, with larger boxes typically costing more. Selecting a junction box with the appropriate capacity helps avoid unnecessary expenses while ensuring that the installation meets the required standards and functionality.

In summary, the capacity of an exterior junction box is a critical factor that impacts safety, functionality, space optimization, and cost-effectiveness. By carefully considering the number of connections required, electricians and homeowners can choose the right junction box for their specific application.

Waterproof

In the world of electrical connections, water can be a formidable foe. That’s why exterior junction boxes, the unsung heroes of outdoor electrical systems, come equipped with IP ratings to safeguard against water ingress and ensure reliable performance.

IP stands for Ingress Protection, and the numbers that follow indicate the level of protection provided against solids (first digit) and liquids (second digit). For exterior junction boxes, the most common ratings are IP65 and IP67, with each offering distinct advantages:

| IP Rating | Protection Against Solids | Protection Against Liquids |

|---|---|---|

| IP65 | Dust-tight | Protected against water jets |

| IP67 | Dust-tight | Protected against temporary immersion in water |

IP65-rated exterior junction boxes provide a robust barrier against dust and water jets, making them suitable for outdoor applications where moisture is a concern. IP67-rated junction boxes offer an even higher level of protection, withstanding temporary submersion in water. This makes them ideal for harsh environments or areas prone to flooding.

Choosing the right IP rating for your exterior junction box is crucial to ensure the longevity and reliability of your electrical connections. By understanding the protection levels offered by IP65 and IP67 ratings, you can make an informed decision that meets the specific demands of your environment.

Size

The size of an exterior junction box, ranging from compact to large, plays a significant role in determining its functionality and suitability for various applications. Here are key considerations regarding the size of exterior junction boxes:

-

Compact Size:

Compact exterior junction boxes are ideal for limited spaces or applications where a small footprint is preferred. They can accommodate a few electrical connections and are often used in residential or light commercial settings, such as for outdoor lighting or security cameras.

-

Medium Size:

Medium-sized exterior junction boxes offer a balance between space and capacity. They can accommodate a moderate number of connections and are suitable for applications such as outdoor power outlets, landscape lighting systems, or small irrigation controllers.

-

Large Size:

Large exterior junction boxes are designed for applications requiring a substantial number of connections. They can accommodate multiple circuits, transformers, or other electrical components. Large junction boxes are commonly used in commercial or industrial settings, such as for outdoor lighting arrays, HVAC systems, or complex irrigation systems.

When selecting the size of an exterior junction box, it is important to consider the number of connections required, the available space, and the specific application. Choosing the right size ensures that the junction box can adequately accommodate the electrical components while maintaining a safe and organized installation.

Shape

The shape of an exterior junction box, whether rectangular, square, or round, is an important consideration that influences its functionality, installation, and overall aesthetics in various applications. Here are key aspects to explore regarding the shape of exterior junction boxes:

-

Rectangular Junction Boxes:

Rectangular junction boxes are widely used due to their versatility and ability to accommodate a range of electrical components. They provide ample space for wiring and connections, making them suitable for both residential and commercial applications. Rectangular junction boxes are often used for outdoor lighting fixtures, power outlets, and security cameras.

-

Square Junction Boxes:

Square junction boxes are popular for their compact size and clean appearance. They are commonly used in residential settings for applications such as ceiling fans, light switches, and electrical outlets. Square junction boxes offer a discreet and space-saving solution for various electrical needs.

-

Round Junction Boxes:

Round junction boxes are specifically designed for use with conduit pipes. They feature a curved shape that allows for easy entry and exit of conduit, making them ideal for outdoor lighting systems, commercial signage, and industrial applications. Round junction boxes provide a weather-resistant seal and ensure a secure connection between the conduit and the electrical components.

When selecting the shape of an exterior junction box, it is important to consider the specific application, the available space, and the desired aesthetics. Rectangular junction boxes offer versatility and ample space, square junction boxes provide a compact and discreet solution, and round junction boxes are ideal for conduit-based applications. By choosing the right shape, electricians and homeowners can ensure a safe, efficient, and aesthetically pleasing installation of exterior junction boxes.

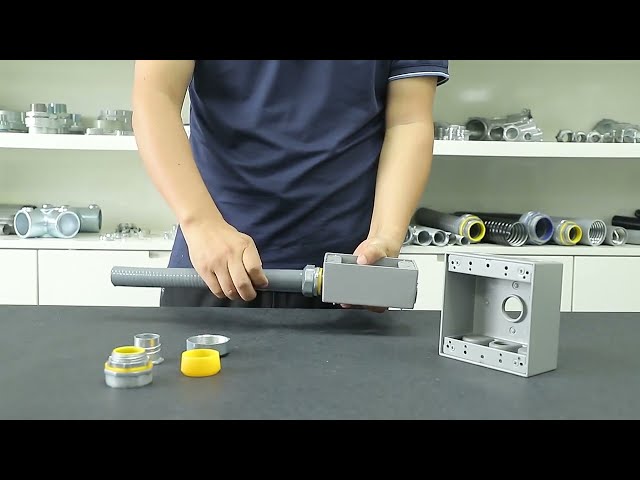

Knockouts

Knockouts, or pre-molded holes, are an integral component of exterior junction boxes, enabling the entry and exit of cables for electrical connections. These knockouts are carefully designed to provide a secure and efficient method of routing cables, ensuring a safe and organized electrical system.

The importance of knockouts cannot be overstated. They allow electricians to easily pass cables through the junction box without the need for drilling or cutting, saving time and effort during installation. Knockouts also maintain the integrity of the junction box, preserving its watertight and dust-tight seal, which is essential for protecting the electrical connections from the elements.

Exterior junction boxes often feature multiple knockouts of varying sizes to accommodate different cable diameters. This flexibility allows for a wide range of electrical configurations and makes it easy to adapt the junction box to specific application requirements. Knockouts also enable the use of conduit fittings, such as connectors and adapters, to create a secure and professional-looking installation.

In summary, knockouts play a crucial role in exterior junction boxes by providing a convenient and reliable method for cable entry. They simplify installation, maintain the integrity of the junction box, and allow for flexible electrical configurations. Understanding the importance of knockouts is essential for ensuring the safety and efficiency of exterior electrical systems.

Table: Key Insights on Knockouts

| Feature | Benefit |

|---|---|

| Pre-molded holes | Easy and efficient cable entry |

| Maintain integrity | Preserve watertight and dust-tight seal |

| Multiple sizes | Accommodate various cable diameters |

| Flexibility | Adapt to different electrical configurations |

Mounting

In the realm of exterior electrical installations, the mounting method of junction boxes plays a crucial role in ensuring, functionality, and aesthetics. Exterior junction boxes can be mounted on walls, poles, or the ground, each option offering distinct advantages and considerations.

-

Wall-mount:

Wall-mounted exterior junction boxes are a common choice for residential and commercial buildings. They are securely attached to a wall surface, providing easy access for maintenance and repairs. Wall-mount junction boxes are ideal for applications such as outdoor lighting fixtures, security cameras, and electrical outlets. -

Pole-mount:

Pole-mounted exterior junction boxes are designed to be attached to utility poles or other vertical structures. They are commonly used for street lighting, traffic signals, and telecommunications equipment. Pole-mount junction boxes offer a flexible and space-saving solution for outdoor electrical installations. -

Ground-mount:

Ground-mounted exterior junction boxes are installed directly on the ground, often used for underground electrical connections or in areas where wall or pole mounting is not feasible. They provide a durable and accessible solution for outdoor applications such as landscaping, irrigation systems, and outdoor event lighting.

When selecting the mounting method for an exterior junction box, factors such as the weight of the junction box and its contents, the desired location, and the environmental conditions should be carefully considered. Wall-mount junction boxes offer a versatile and convenient solution, while pole-mount and ground-mount junction boxes provide specialized options for specific applications. By understanding the advantages and considerations of each mounting method, electricians and homeowners can choose the most appropriate solution for their exterior electrical needs.

Code compliance

In the realm of exterior electrical installations, code compliance is paramount. Exterior junction boxes play a critical role in ensuring the safety and reliability of electrical systems by adhering to established electrical codes and standards.

Electrical codes and standards are comprehensive sets of rules and regulations that govern the design, installation, and maintenance of electrical systems. These codes are developed by experts in the field and are based on years of research and experience. By adhering to these codes, electricians and homeowners can minimize the risk of electrical fires, shocks, and other hazards.

Exterior junction boxes that meet electrical codes and standards are designed and manufactured to withstand the harsh outdoor environment. They are made of durable materials that can resist moisture, temperature fluctuations, and UV rays. Code-compliant junction boxes also feature proper grounding and bonding to ensure the safety of electrical connections.

The importance of code compliance cannot be overstated. Electrical codes and standards are in place to protect people and property from electrical hazards. By using exterior junction boxes that meet these codes, electricians and homeowners can help ensure the safety and reliability of their electrical systems.

Table: Key Insights on Code Compliance for Exterior Junction Boxes

| Feature | Benefit |

|---|---|

| Adherence to electrical codes and standards | Ensures safety and reliability of electrical systems |

| Durable materials | Withstand harsh outdoor environment |

| Proper grounding and bonding | Protects against electrical hazards |

Warranty

The warranty period for an exterior junction box, typically ranging from 1 to 5 years, plays a significant role in determining the long-term reliability and peace of mind for property owners and contractors.

A comprehensive warranty provides assurance that the manufacturer stands behind the quality and durability of their product. It guarantees that the junction box will perform as intended and be free from defects in materials and workmanship for the specified period. This coverage offers peace of mind, knowing that any potential issues can be addressed promptly and without additional expenses.

The length of the warranty is often indicative of the manufacturer’s confidence in the quality of their product. Longer warranties, such as 5 years or more, demonstrate a higher level of trust in the junction box’s ability to withstand the elements and perform reliably over an extended period.

When selecting an exterior junction box, it is essential to consider the warranty period and the reputation of the manufacturer. A reputable manufacturer with a proven track record of producing high-quality products is more likely to offer a comprehensive warranty. By choosing a junction box with a generous warranty, property owners and contractors can minimize the risk of unexpected repair or replacement costs, ensuring long-term value and satisfaction.

Table: Key Insights on Warranty for Exterior Junction Boxes

| Warranty Period | Benefits |

|---|---|

| 1-2 years | Basic level of protection against defects |

| 3-4 years | Moderate level of coverage, providing additional peace of mind |

| 5+ years | Extended warranty period, demonstrating manufacturer’s confidence in product quality |

FAQs

Exterior junction boxes are essential components of outdoor electrical systems, providing protection and organization for electrical connections. Here are some frequently asked questions and answers to help you understand and effectively utilize exterior junction boxes:

Question 1: What is the purpose of an exterior junction box?

An exterior junction box serves as a protective enclosure for electrical connections and components in outdoor environments. It safeguards these connections from moisture, dust, and other environmental factors, ensuring the reliable and safe operation of outdoor electrical systems.

Question 2: What materials are exterior junction boxes made of?

Exterior junction boxes are typically made of durable materials such as plastic or metal. Plastic junction boxes offer cost-effectiveness and insulation, while metal junction boxes provide enhanced durability and corrosion resistance for demanding outdoor conditions.

Question 3: What factors should be considered when choosing an exterior junction box?

When selecting an exterior junction box, consider factors such as the number of connections required, the size and shape of the box, the material and its suitability for the environment, the mounting method, and compliance with electrical codes and standards.

Question 4: How should exterior junction boxes be installed?

Exterior junction boxes should be installed according to local electrical codes and by qualified electricians. Proper installation involves selecting the appropriate location, securely mounting the box, and making proper electrical connections while maintaining watertightness.

Question 5: What is the importance of proper sealing for exterior junction boxes?

Proper sealing is crucial for exterior junction boxes to prevent moisture penetration and ensure the safety and reliability of electrical connections. Use gaskets, sealants, and other sealing methods to maintain a watertight seal, protecting the box from harsh outdoor conditions.

Question 6: How often should exterior junction boxes be inspected and maintained?

Regular inspection and maintenance of exterior junction boxes are essential to ensure their proper functioning and longevity. Inspect for any signs of damage, corrosion, or loose connections. Clean the box and tighten connections as needed, and replace any damaged components promptly.

In conclusion, exterior junction boxes play a vital role in ensuring the safety, reliability, and efficiency of outdoor electrical systems. By understanding their purpose, selecting the appropriate junction box, installing it correctly, and performing regular maintenance, you can ensure the optimal performance and longevity of your outdoor electrical connections.

Transition to the next article section: Types of Exterior Junction Boxes

Exterior Junction Box Tips

Exterior junction boxes are essential for protecting electrical connections outdoors. Here are some tips to help you choose, install, and maintain exterior junction boxes:

Tip 1: Choose the Right Junction Box

Consider the number of connections, the size and shape of the box, the material, and the mounting method. Make sure the junction box is rated for outdoor use and meets local electrical codes.

Tip 2: Install the Junction Box Properly

Follow the manufacturer’s instructions for installing the junction box. Make sure the box is securely mounted and that all connections are tight. Use weatherproof gaskets or sealant to keep moisture out.

Tip 3: Protect the Junction Box from the Elements

Install the junction box in a location that is protected from direct sunlight and rain. If possible, mount the box on a wall or post instead of burying it underground.

Tip 4: Inspect the Junction Box Regularly

Inspect the junction box regularly for any signs of damage or corrosion. Tighten any loose connections and replace any damaged components.

Tip 5: Use the Right Tools and Materials

Use the right tools and materials for the job. This includes using a voltage tester to check for power before working on the junction box, and using waterproof connectors and sealant to protect the connections.

Summary of Key Takeaways:

- Choose the right junction box for your application.

- Install the junction box properly.

- Protect the junction box from the elements.

- Inspect the junction box regularly.

- Use the right tools and materials.

By following these tips, you can help ensure that your exterior junction boxes are safe and reliable.

Transition to the article’s conclusion:

Exterior junction boxes are an important part of any outdoor electrical system. By following these tips, you can choose, install, and maintain exterior junction boxes that will protect your electrical connections and keep your outdoor space safe.

Conclusion

Exterior junction boxes play a critical role in the safety and functionality of outdoor electrical systems. They protect electrical connections from the elements and provide a convenient way to access and maintain electrical components. When choosing an exterior junction box, it is important to consider the number of connections, the size and shape of the box, the material, the mounting method, and the IP rating. It is also important to install the junction box properly and to protect it from the elements.

By following the tips outlined in this article, you can choose, install, and maintain exterior junction boxes that will protect your electrical connections and keep your outdoor space safe. Exterior junction boxes are an essential part of any outdoor electrical system, and by understanding their importance and following best practices, you can ensure that your electrical system is safe and reliable.

Youtube Video: